Made to Shade: NovaShield

Our team name was Made to Shade and the product we created was called the NovaShield. NovaShield is a retractable awning for powered wheelchairs intending to give people with ALS more access to activities involving sunlight. The team consisted of Moriah Brooks, Shanna Fischzang, Dominick Triplett, and myself. This project was done as part of our Senior Team Design in Biomedical Engineering class at Tulane University. We also drafted a provisional patent for this device as part of the class that was looked at by a professional in order to perfect. The idea behind this device was to make it easy to manufacture and provide instructions on how to make it so that people who care for PALS (people with ALS) can build it and give their PALS full access to activities involving sunlight without significantly adding to their already enormous costs of care. We drafted the provisional patent to ensure that nobody could commercialize our device as we wanted the building instructions available to all for no cost. This project was done from August 2020- May 2021.

This is our final prototype of the NovaShield.

We performed many tests and confirmed that our device fulfills its intended purpose of allowing eye tracking technology to function in the presence of sunlight, while still allowing the PALS to see what is going on around them.

The Background

The inspiration for our device started with two team members having an summer internship at Team Gleason leading into our senior year. Team Gleason is a foundation, founded by former NFL Player Steve Gleason, that aims to help people diagnosed with ALS. ALS is a neurodegenerative disease in which people lose control of their muscles due to degradation of motor neurons. PALS often use eye-tracking technology to move around in their powered wheelchairs and communicate. The tablet seen in the picture contains this eye-tracking technology and was loaned to us by Team Gleason. One major issue with this eye tracking technology is that is uses infrared radiation to read the location of the users eyes which can be seriously compromised by the infrared radiation from direct or indirect sunlight rendering these PALS unable to move or communicate effectively. There are now some versions of eye tracking technology on that market that do not that this issue but they are very new and very expensive.

Retractability

Retractability was a major focus for our group. This was a major focus because we didn’t want our user to feel trapped in this shaded bubble when it wasn’t necessary for movement and communication. Our device can be easily deployed and retracted by loosening the bolt on the side of the chair where the awning is attached. The image on the left has our awning retracted while the image on the right shows the awning deployed.

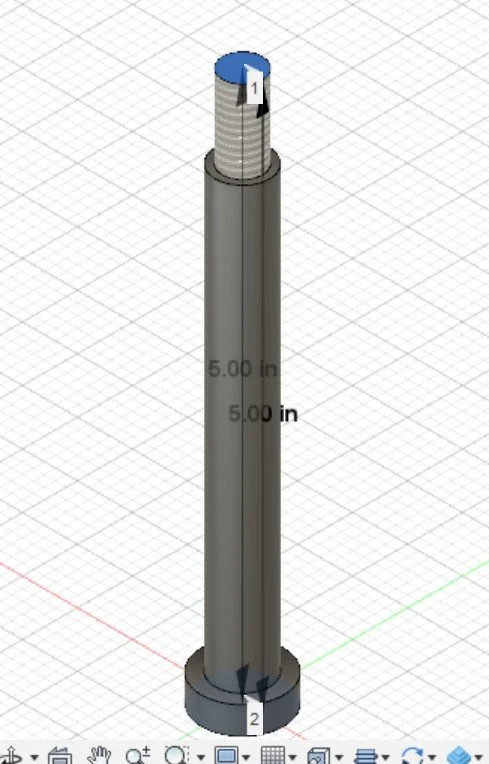

The Connection to the Chair: The Bolt

The connection point of our awning to our chair was this bolt. The one that came with the chair was not long enough to allow for further attachments aside from the arm of the chair itself. I started by designing a longer model of this bolt in Fusion 360 for my group to use as the attachment point which can be seen in the image on the left. I first 3D printed it to make sure it would fit and then machined a metal version of it on the CNC lathe in the Tulane MakerSpace which can be seen in the middle picture. Unfortunately, the thread count I determined from the original bolt was incorrect due to it having been worn down by time and continual use and the machined bolt did not fit perfectly. This led us to eventually order correctly sized bolts from McMaster as we did not have time to remanufacture. The image on the right shows the bolt being attached with the awning connected to the chair.

The Shaping of the Acrylic

We decided to make our awning out of acrylic fitted with car window tint after determining that this would block the necessary amount of infrared to allow the eye tracking technology to function properly in direct sunlight. We started with one large sheet of acrylic which we then cut into one foot wide strips. We then created the mold seen in the left image using bent metal and wood to bend all the acrylic strips to the same angle. After that, we applied careful and consistent heat to the sheets of acrylic allowing them to all bend evenly over our mold and become the right shape. We then drilled holes in the bottom of each strip on each side to allow for them to be attached to the chair. We also reinforced these holes with acrylic washers, that I designed and cut on a laser cutter in the Tulane MakerSpace, in order to be sure they wouldn’t crack while in use. The image on the right shows one of the acrylic sheets after shaping before the infrared blocking tint was applied.

The Shading

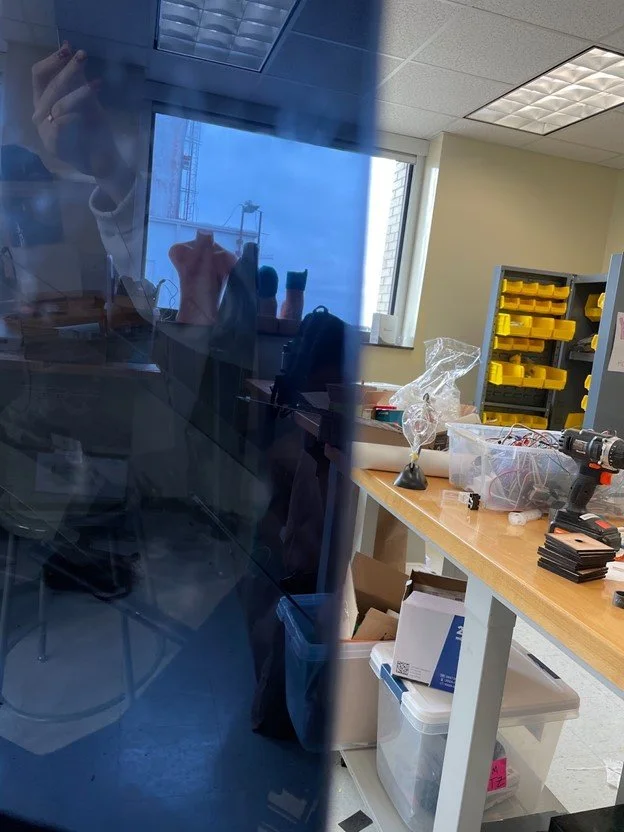

After preliminary testing, we decided we would use acrylic fitted with car window tint to block the infrared rather than a welding curtain that we had previously discussed. This car window tint put onto the acrylic blocked enough infrared for the eye tracking technology inside of its protection to function properly. In the image on the left you can see the visibility through the tint versus regular visibility. The image on the right shows our awning applied to the chair with only one acrylic strip tinted so that the contrast between the tinted and un-tinted can be easily seen.

The Original Prototype

This was the first prototype we created. It was not retractable. This prototype had PVC pipe making up its internal structure with an attachment point at the back of the chair. The covering over the structure was made up of a plastic couch protector cut to our dimensions with infrared blocking car window tint applied. The tint did not apply very evenly to this very flexible surface and had many bubbles. One of the issues with this prototype was that the back attachment point was much less universal among powered wheelchairs that the bolts that connects the arms of the chair. Another issue with this prototype was that it was not very stable or visually appealing. A third, and most important issue with this prototype, was that it did not provide enough coverage to block out all of the infrared interfering with the eye tracking technology. The sides of the user also need to be covered as sunlight bouncing off the ground and into the line of use by the eye tracking technology also negatively affected its use.