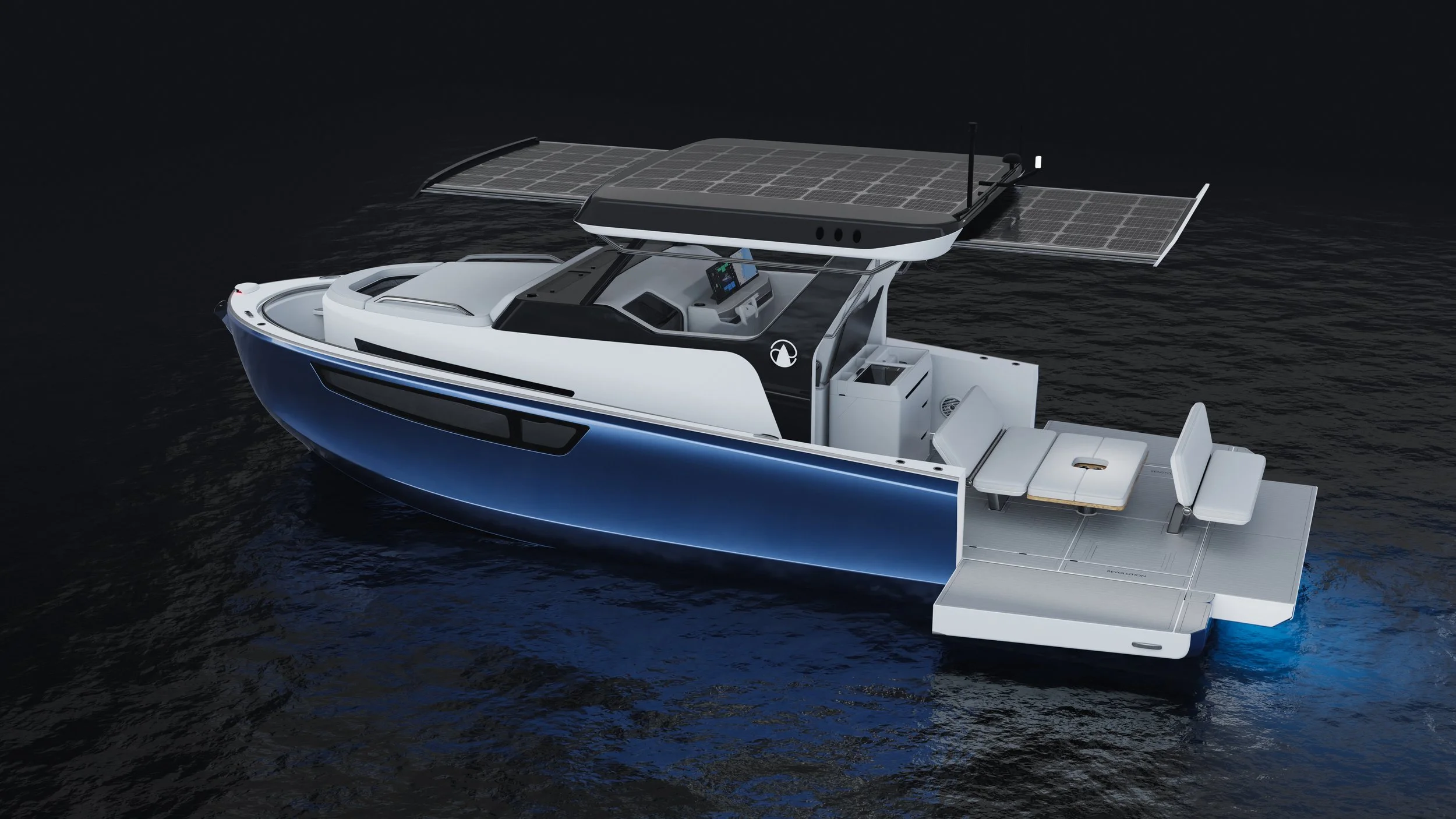

R30

The R30 is a 30-foot electric in-board motor boat designed by Blue Innovations Group. The R30 has 800 horsepower, a 12-person capacity, and an 8-hour nominal run time with a 221 kWh battery pack. This boat is also able to charge using the solar panels on the extended canopy. I had the pleasure of being part of the mechanical design team for the beta version of the R30 prototype which was designed with production intent. Below is a rendering of the final model of the R30.

The Beta Prototype

This image on the right is of the beta prototype that we built at the Blue Innovations Group manufacturing facility in St. Petersburg, Florida. It truly was an amazing feat to see how the mechanical, electrical, battery, and operations teams came together to bring this prototype to reality. This prototype had nearly all of the functionality of the finished production intent boats ready to be sold to customers.

My Contributions

Every member of the teams at Blue Innovations Group contributed to the design and building of many parts of our beta boat. As part of the Mechanical Design Team, I was particularly involved with the design and building of many of the physical aspects of this boat. My main project at the beginning of the design process was designing all of the metal structures that constitute the helm area (where the driver would sit). I spent many hours designing these structures, running simulations to ensure they would be sturdy enough to support the canopy in all sorts of loading conditions (using Simscale and Ansys), and ensuring they would properly interface with the other structures of the boat around them. This process also involved a lot of inter-team collaboration as there are a lot of electronics and mechanisms that are housed within the helm area and I needed to make sure every system had room to be properly placed. I also played a large role in leading the effort to ensure that all of our structures in and around the cabin would be watertight making sure the cabin would stay dry under many different conditions including heavy rain or pressure washing. Other areas where I led the design included railings around the boat, doors around the boat, and trim attachment on all sorts of surfaces. I also was the lead designer for the HVAC system of the beta boat and was able to design and source all components for a fully functional HVAC system for the cabin.

The Railings

One of the projects that I oversaw was the railings on board the R30. This included one railing that wrapped around the gunnel of the boat, two railings on the front lounge, and two railings on the canopy (the canopy railings were designed and manufactured but didn’t make it onto the beta boat). I spoke to many different vendors to compare and contrast pricing and quality before making a final decision about who to manufacture these railings. Despite the gunnel railing being over 20 feet long it came out very nice and felt very sturdy. The railings were delivered in pieces and with the help of some of my colleagues I was able to assemble them and install them onto our beta boat.

The Doors

Another area of the boat where I took the lead in designing was the doors. The doors included the sliding cabin door that was the entryway into the cabin and the two bi-fold doors that were for the bathroom and the closet within the cabin. I explored a lot of different material options and manufacturing processes before choosing to go with acrylic. Working with our industrial designer we decided that acrylic was the most effective way to get close to the desired asthetic and strength.

The Interior

These are two views from the cabin of the beta boat. The view on the left looks into the cabin from the door and the view on the right looks out of the cabin from the head of the table (this table lowers so the whole area can be turned into a bed).